The compact and well-priced MP180 planer with 3-in-1 functions saves operational costs and time while producing furniture-grade timber, tongue and grove boards and mouldings.

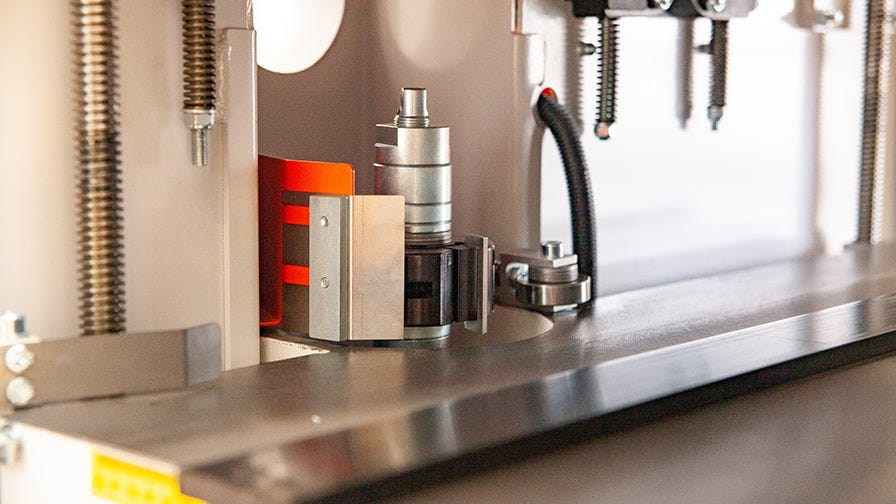

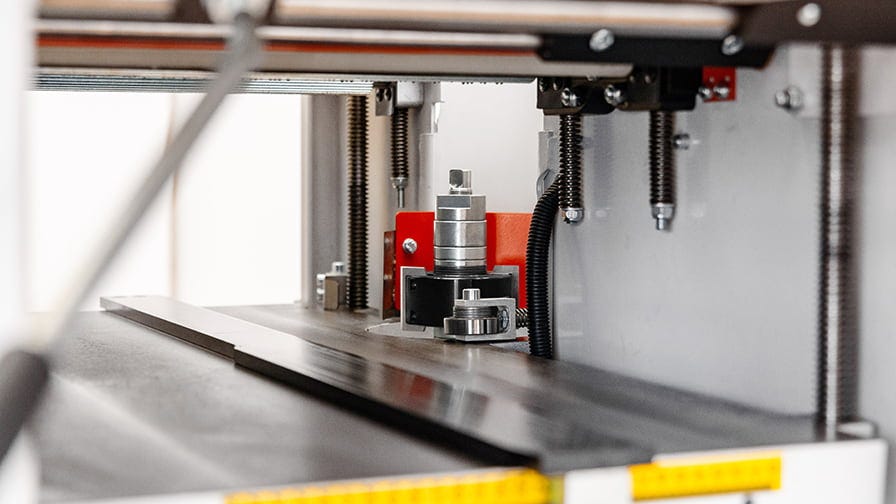

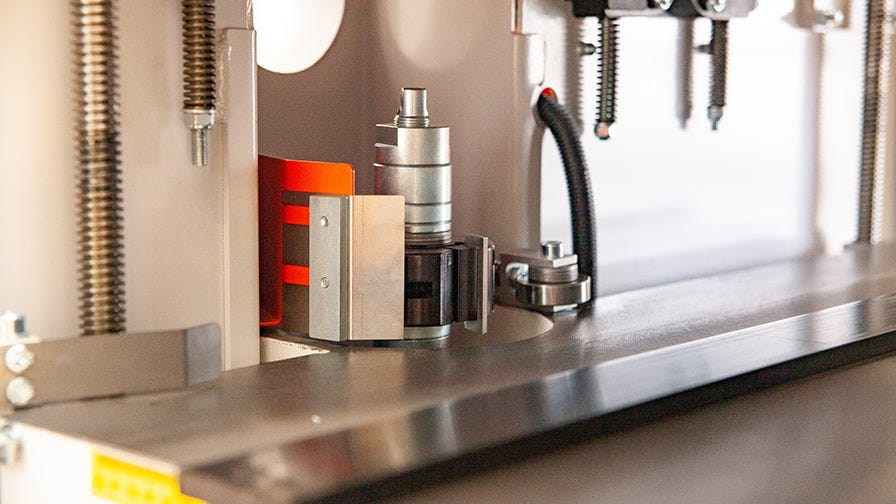

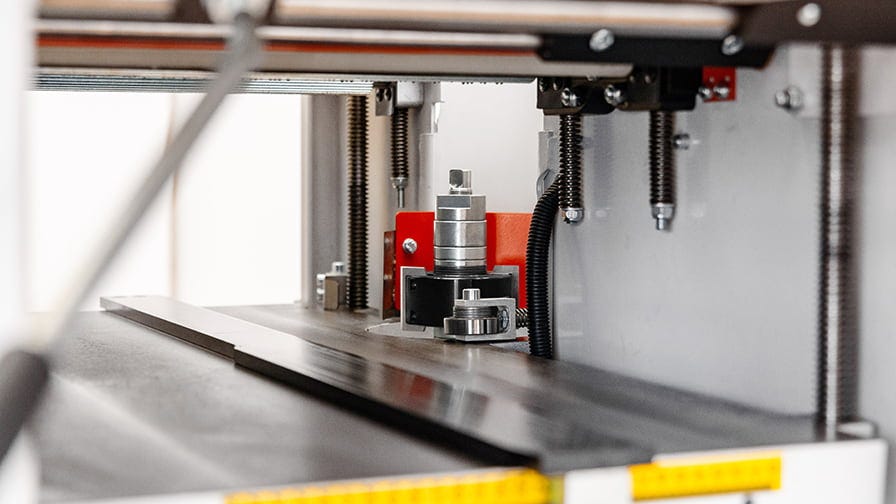

The MP180 multi-planer developed by Wood-Mizer has one horizontal cutter for planing and thicknessing and one side cutter added to the lower table for moulding. One of the smallest machines in Wood-Mizer’s Moulders / Planers range, the MP180 produces finished square boards and mouldings in two passes compared to the required six or eight passes with a standard thickness planer.

The processing starts by using the top table for making two adjoining sides perfectly flat and creating precise right angles to each other. Then the last two sides are processed on the bottom table, thicknessing the board to its final dimensions.

"You can take out any bow from your dried timber using the MP180 to end up with a perfectly flat timber,” says Mr. Keith Threadgall, a woodworker from Scotland. "Once one surface is flat, you can run it underneath with the thicknesser as the opposite surface will be perfectly flat – parallel to the first surface."

By utilizing the horizontal cutter for planing / thicknessing and the vertical side cutter to mould, the MP180 operates in 3 functions - planing, thicknessing, and side moulding - without having to reconfigure the machine.

Several features make the MP180 multi-planer design unique:

- The thickness width is 410 mm - bigger than most competitors on the market

- Thickness height of 260 mm

- Additional side spindle can mould up to 100 mm high

- Cast iron bed is heavy and reduces machine’s vibration while increasing reliability

- Easily adjusted top planing knife guard improves safety of operation

- The horizontal cutter is supplied with 2 knives as standard. For a smoother finish, a cutter with 4 knife slots is available as an option.

- The feed speed is constant at 6 m/min as standard. For large hardwood processing the optional variable feed speed between 2-12 m/min is available.

- Aluminum side fence tilts up to 45 degrees.

"Even when making a 4” by 4” square beam you don’t always want it solid square,” continues Mr. Keith Threadgall. "With the tilt fence you can easily add a light 45 degrees bevel on it, to make sure it is not sharp and to improve its aesthetics. This adds value to the finished timber."

The benefit is that you can profile and thickness the board at the same time. Having a spare spindle for your vertical side cutter allows you to easily change your profiling knives and in two passes produce tongue and groove boards.

The smart design of the MP180 consists of two separate drive motors, one for the top cutter block and one for the side spindles. These two motors can be started individually, depending on your requirements – this allows for extra electricity cost savings during operation.

"This is hand in hand with Wood-Mizer’s mentality to use narrowband thin-kerf blades to save on steel, energy consumption and wasted timber. Not running all motors at the same time also reduces your maintenance costs including blades, belts, and bearings," concludes Radoslaw Adamkiewicz, Wood-Mizer Product Manager.

This unique combination of functionality and quality with an affordable price makes the MP180 the obvious choice for carpenters who want to have one machine instead of three to save on operational costs, production space and time.

* * *

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, planer/moulders, material handling equipment, sawmill blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.